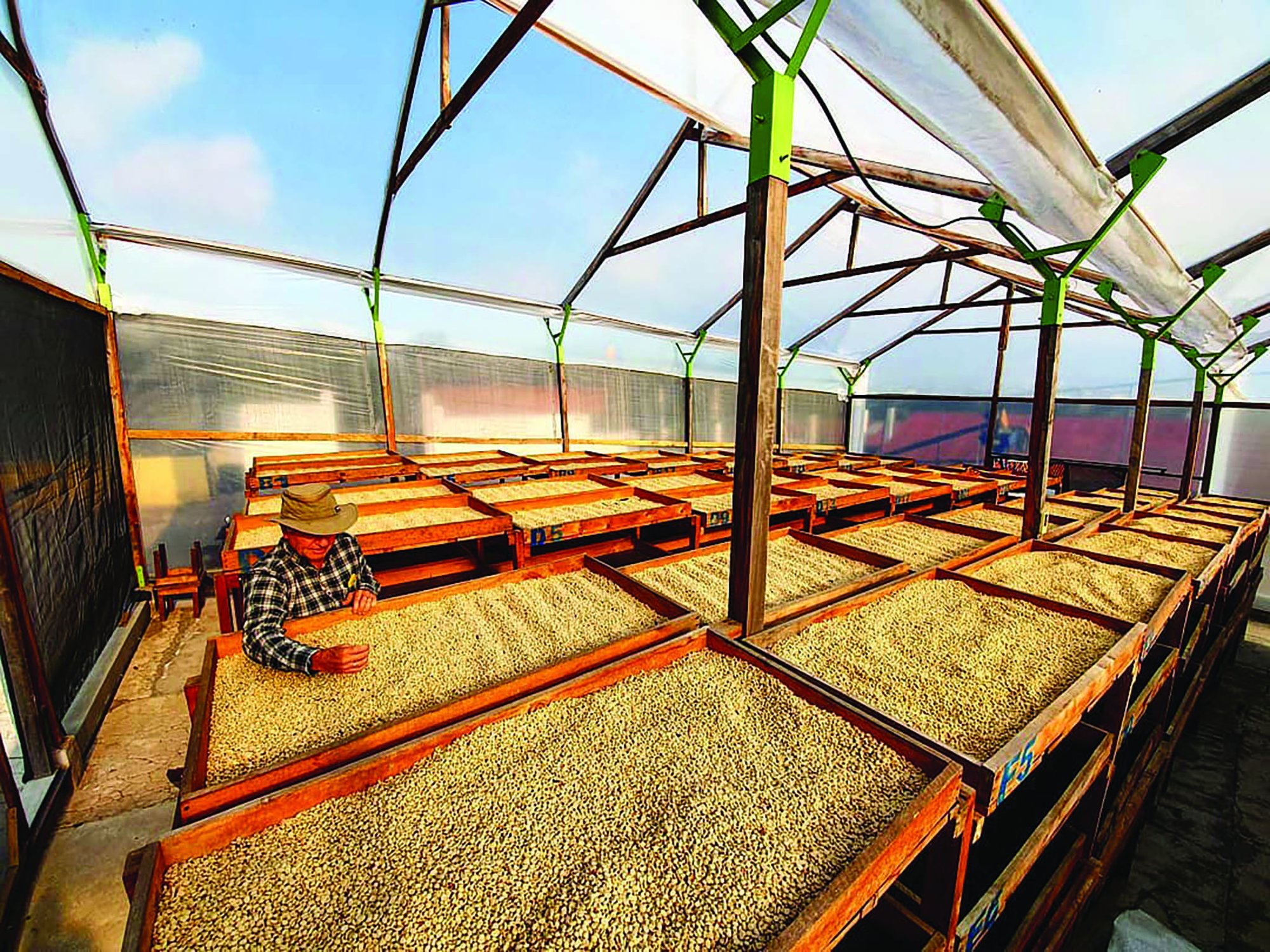

Washed coffee on the drying surface in Guatemala. Photo courtesy of Finca Capetillo.

It’s been said that the Antigua Valley region of Guatemala is to coffee what regions like the Walla Walla Valley and Sonoma County are to wine here in the United States — unique agricultural lands with a strong past of producing exceptional beverages.

Strategically located in the Antigua Valley, the Finca Capetillo coffee farm was built between the Agua, Fuego, and Acatenango volcanoes, a region perfect for producing coffee. The high altitude and rich volcanic soil provide a unique ecosystem for growing coffee.

Finca Capetillo was purchased by José Mariano Rodriguez back in 1874. Since then, the farm has been passed from generation to generation, introducing new and modern-day agricultural advancements along the way. This has made Capetillo the gold standard for better agriculture practices in the country.

We asked our coffee hunter Fredy Bolanos, a professional coffee trader at Café Cubo, what makes coffee from this particular region unique. “It all starts with quality control,” Bolanos said. “Quality at the farm and the export level is the backbone of making sure we not only produce the best coffees but the highest quality by volume as well.”

Bolanos went on to say that while this region prides itself on choosing only the best cherries for its coffee beans, quality control starts even before harvest. “Taking care of our plants is the secret. We use only the best organic fertilizers, coffee pulp, and cherry tree maintenance throughout the year, which is vital to our success.” In addition, the mild temperatures of 68 to 79 degrees Fahrenheit during the day and 50 to 65 degrees at night are ideal for producing exceptional coffee.

Into the Wash

Finca Capetillo in Guatemala can produce up to 50,000 bags — with each bag weighing in at roughly 100 pounds each — of ripe coffee each harvest. Bolanos explained that the washed process was developed to optimize post-harvest coffee preparation and as an efficient method to quickly dry and store the coffee beans to maintain their freshness.

The washed process, also sometimes called the wet process, is common in many coffee-growing countries worldwide. The methods and equipment used to perform this type of processing may differ from region to region, but the technique is universal.

This process, which quickly removes the coffee fruit from the seed shortly after the coffee is picked from the tree, can be an efficient way to prepare coffee seeds — the beans — for export in climates with cool overnight temperatures and good sun exposure during the day. It’s also a space-saver for small producers, who perform much of the green coffee cultivation on the farm itself.

It starts by harvesting the ripe cherries from the coffee trees, with quality control being a critical factor. Both the farmers and workers in the field are trained to select only the ripest cherries, which can be dark red, bright red, purple, or even yellow, depending on the variety.

The cherries are carefully picked by hand and carried to a receiving point for depulping. But before the depulping process starts, the ripe cherries are weighed, rinsed, and given their first sort for quality.

Next, workers at Capetillo perform a float test of their coffee cherries. The cherries are submerged in water, and any that float to the top of the tank are immediately discarded from the batch. This is an easy indicator of a defect in the fruit.

The whole coffee fruit is then put through the depulping machine. This machine squeezes the seed out of the tough, cherrylike skin known as the fruit’s pulp. Depulping typically happens as soon as possible in the washed process, usually within eight to 12 hours of the harvest.

After depulping, a sticky fruit material called mucilage remains on the seeds. This mucilage is removed throughout the washing process. The sticky seeds are then typically transferred to a fermentation tank.

“The pulp left over from the seed is usually used for compost or fuel, or it is discarded,” Bolanos said. “The sticky seeds are kept dry in an open fermentation style, which means they are not submerged in water during the fermentation. Instead, the seeds will be left like this overnight to ferment in the tank.”

Spin Cycle

Fermentation is a natural occurrence and happens in every type of post-harvest processing. Coffee producers will try to mitigate the time, temperature, and velocity of fermentation in the washed method. Fermentation helps soften the fruit mucilage, making it easier to remove in the washing. The fermentation process also enhances the specific flavors of the coffee-producing region.

After roughly 12 to 18 hours of fermentation, the actual washing begins. The producer first makes sure that the mucilage has fermented enough by inspecting a sample with his hands to feel how sticky or tacky the material is. He then fills the tank with fresh water to submerge the coffee. A long wooden tool is then used to agitate the seeds.

The agitation in the water removes the mucilage, leaving the coffee clean in its parchment layer for drying.

“This is where having a clean, fresh water source at the farm is of vital importance,” Bolanos said. “This farm will repeat washing the coffee by draining the murky water out and refilling the tank with fresh, clean water. Capetillo Farm washes the seeds a minimum of three times during this process. The water used in this needs to be purified, treated, or disposed of very carefully.”

He explained that the fruit mucilage left behind during the washing process would contaminate freshwater and groundwater sources if not disposed of properly, which could have devastating effects on future harvests.

Sorting and Drying

Once the seeds are clean of mucilage and undergo a final float test, the producer does yet another quality sort. He brings the washed coffee to the drying patios and uses a portable sorting table that allows him to remove any remaining coffee cherry husks, as well as defective or deformed beans.

After this final sort, the producer brings the washed coffee to the drying surface and spreads out the coffee beans.

The drying environment is designed to control the temperature and airflow for both efficiency and quality. With a wooden rake, the seeds are spread into a thin layer on the patio. Capetillo also uses a raised-bed method of drying the beans depending on the type and volume of the harvest.

Throughout the drying process, the coffee will be raked several times to ensure it dries evenly. Here in the Antigua Valley, it takes anywhere between seven and 11 days for the coffee to completely dry, depending on the weather.

After the coffee is dried, it is transported to a storage unit or warehouse in its parchment layer, where it will rest in sacks until it is ready to be exported. Then the parchment will be removed, and the coffee will be shipped to its predetermined exporter.

Witnessing the entire process of washing the coffee was an experience worthy of a bucket list — and provided a greater understanding of the seed-to-cup journey these little coffee beans take to reach our favorite stateside roasters.

This article first appeared in the Fall 2021 print edition of Coffee or Die Magazine as “So Fresh and So Clean.”

Read Next:

Kelly Getzelman is a former staff writer for Coffee or Die Magazine. A retired Navy SEAL chief petty officer, Getzelman has nearly two decades of special operations experience and is always ready to ship out on his next epic coffee adventure.

BRCC and Bad Moon Print Press team up for an exclusive, limited-edition T-shirt design!

BRCC partners with Team Room Design for an exclusive T-shirt release!

Thirty Seconds Out has partnered with BRCC for an exclusive shirt design invoking the God of Winter.

Lucas O'Hara of Grizzly Forge has teamed up with BRCC for a badass, exclusive Shirt Club T-shirt design featuring his most popular knife and tiomahawk.

Coffee or Die sits down with one of the graphic designers behind Black Rifle Coffee's signature look and vibe.

Biden will award the Medal of Honor to a Vietnam War Army helicopter pilot who risked his life to save a reconnaissance team from almost certain death.

Ever wonder how much Jack Mandaville would f*ck sh*t up if he went back in time? The American Revolution didn't even see him coming.

A nearly 200-year-old West Point time capsule that at first appeared to yield little more than dust contains hidden treasure, the US Military Academy said.